Crack Stitch Case Study

Stitching and Sealing – The Ultimate Crack Repair

We get asked a lot if a crack should be filled when installing Crack Stitches. The answer is overwhelmingly: YES! There are several reasons for this:

- While carbon will stop and expansion, it will not stop contraction. You want to prevent the crack from closing.

- Aesthetics.

- Prevent future water entry.

There are a couple steps and techniques that can be utilized.

When stitching walls:

Is there water coming through the crack?

If so, a ported crack injection might be best. This seals the entire crack from front to back, not just visible section of the crack. Doing this will require an injection epoxy instead of using the 4070 epoxy offered with the Crack Stitch kits.

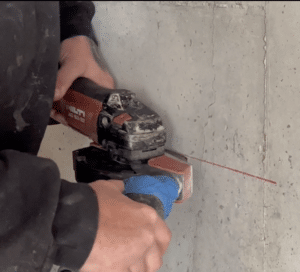

Step 1: Measure and saw cut for your stitches.

Step 2: Vacuum out the crack

Step 3: Insert stitches

Step 4: Apply a surface seal and injection ports.

Step 5: Inject epoxy into the ports, starting from the bottom. Place cap over each port when complete. This both seals the crack and bonds the stitches. You do not need to use the 4070 epoxy to bond the stitches in this application.

Step 6: Grind or hammer drill the surface seal and ports off if desired for aesthetic purposes and finishing

If no water is present:

Step 1: Measure and saw cut for your stitches.

Step 2: Widen the crack with a crack chaser blade if necessary. Recommend 1/4” - 3/8”

Step 3: Vacuum out the crack.

Step 4: Fill the crack and stitch cuts with epoxy or mortar

Step 5: Insert stitches

Step 6: Trowel or smooth with putty knife

Step 7: Grind or sand as desired for aesthetics and finishing

When Stitching Slab Floors:

Step 1: Measure and saw cut for your stitches.

Step 2: Widen the crack with a crack chaser blade if necessary. Recommend 1/4” - 3/8”

Step 3: Power-wash if using mortar. Vacuum if using epoxy.

Step 4: Fill the crack and stitch cuts with epoxy or mortar

Step 5: Insert stitches

Step 6: Trowel or smooth with putty knife

Step 7: Grind or sand as desired and apply coatings if desired