Crack Stitch Case Study

The Science of Slab Crack Repair

Cracks in slabs can appear for a variety of reasons. Regardless of the cause there are some fundamental techniques that should always be followed. These techniques apply to all type of crack movement: heaving, settlement, vertical shear, and lateral shear.

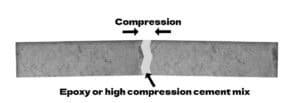

First, we want to create compression between the slabs on either side of the crack. When compression is created, the two slabs press against each other and prohibit any further uplift, settlement, or lateral movement. Compression is created by completely filling the crack with a high compression material such as a structural epoxy, injection epoxy, cement based material, or an expansive foam.

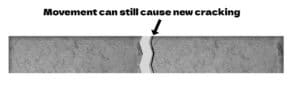

Filling the crack alone does not guarantee those compressive forces. The slab still has the freedom to expand at the crack, which can break the bond between the sections on either side of the crack.

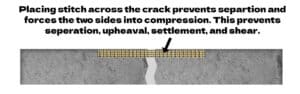

Stitch the crack stops this from happening. By installing high strength, non-corrosive carbon across the crack, we prevent any separation from occurring. This guarantees the compression is maintained and the crack can no long heave, settle, shear, or expand.

On the flip side, stitching alone does not fix the crack. While the stitch can play a role in stopping compressive movements, it’s effectiveness is multiplied when used in conjunction with a high compressive material.

Have any additional questions on slab crack repair? Contact our engineering team at Fortress today.